As the winds die down next week, we will depart George Town to cruise north thru the Exuma chain of islands, then stay in Spanish Wells for about a month. We will miss our friends & the beautiful blue water, but not the “George Town Shuffle”. Every 5 – 8 days, approaching cold fronts cause the easterly trade winds to clock around to the south, then west (usually in the 30’s & sometimes gusting to the 40’s) before north & back to the east. Hiding has become more difficult as the best protected anchoring areas have been closed off – now declared a protected park with just some moorings in one limited area instead. Recently, the count of cruising boats just passed 300 (yes, there is an organized count once a week) – confirming it’s time to leave!

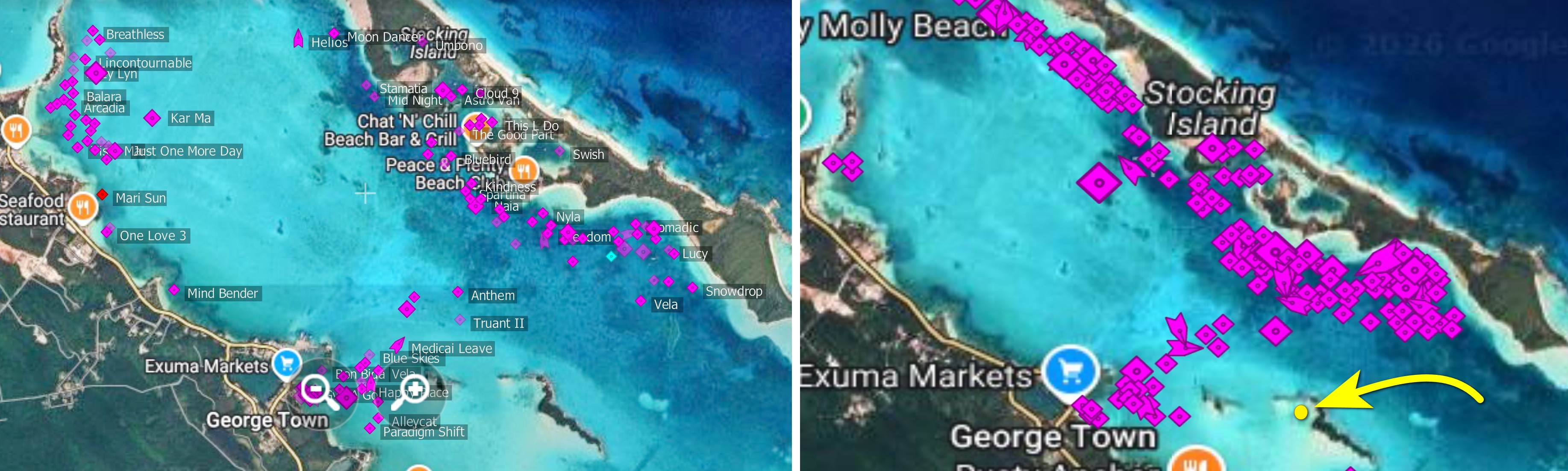

The left photo shows a cold front’s approach when most boats (purple squares) scatter all over. The right photo shows most boats back “to normal”. Lots of boats? There are actually more than twice this many, as these represent only boats who transmit an AIS signal. The yellow arrow on the right indicates our favorite semi-private, semi-protected spot with less than 4′ of depth & only 3′ on approach at low tide. Nice when we can snag it first after returning from a strong cold front (W – NW winds bring in waves, so we also have to “shuffle” off elsewhere, usually to the “Litterbox” – a shallow area with only depth enough for cats – get it?).

The left photo shows a cold front’s approach when most boats (purple squares) scatter all over. The right photo shows most boats back “to normal”. Lots of boats? There are actually more than twice this many, as these represent only boats who transmit an AIS signal. The yellow arrow on the right indicates our favorite semi-private, semi-protected spot with less than 4′ of depth & only 3′ on approach at low tide. Nice when we can snag it first after returning from a strong cold front (W – NW winds bring in waves, so we also have to “shuffle” off elsewhere, usually to the “Litterbox” – a shallow area with only depth enough for cats – get it?). Looking out to 1′ – 2′ waves out in the main harbor during an average cold front. The next cold front brought 2′ – 3′ waves with many boats dragging anchor, snapping their anchor bridles & even one of the new, “secure” moorings breaking free.

Looking out to 1′ – 2′ waves out in the main harbor during an average cold front. The next cold front brought 2′ – 3′ waves with many boats dragging anchor, snapping their anchor bridles & even one of the new, “secure” moorings breaking free. To make things more interesting, one night there was a geomagnetic storm which interfered with GPS signals we depend on for navigation, including anchor drag apps (this shows our track while anchored & you set the circular zone you expect to stay within). Our anchor drag siren blasted away & showed us slowly dragging anchor out of our set zone. Engines started, spotlights out we noticed the fish trap float 30′ behind … was still 30′ behind us. Plus knowing our anchor was completely buried in good sand, we quickly knew this was a false alarm. Back to bed, but checking later, noticed that we magically “un-drug” an hour later, back into our circle. (Lori says- that drag alarm siren is damn heart pounding & why always at night?) Many other boats experienced similar anomalies such as dragging forward or moving around in circles.

To make things more interesting, one night there was a geomagnetic storm which interfered with GPS signals we depend on for navigation, including anchor drag apps (this shows our track while anchored & you set the circular zone you expect to stay within). Our anchor drag siren blasted away & showed us slowly dragging anchor out of our set zone. Engines started, spotlights out we noticed the fish trap float 30′ behind … was still 30′ behind us. Plus knowing our anchor was completely buried in good sand, we quickly knew this was a false alarm. Back to bed, but checking later, noticed that we magically “un-drug” an hour later, back into our circle. (Lori says- that drag alarm siren is damn heart pounding & why always at night?) Many other boats experienced similar anomalies such as dragging forward or moving around in circles. We enjoyed many brilliant rainbows as light showers occasionally passed by offshore.

We enjoyed many brilliant rainbows as light showers occasionally passed by offshore. The combination of light winds & a full moon was a special treat.

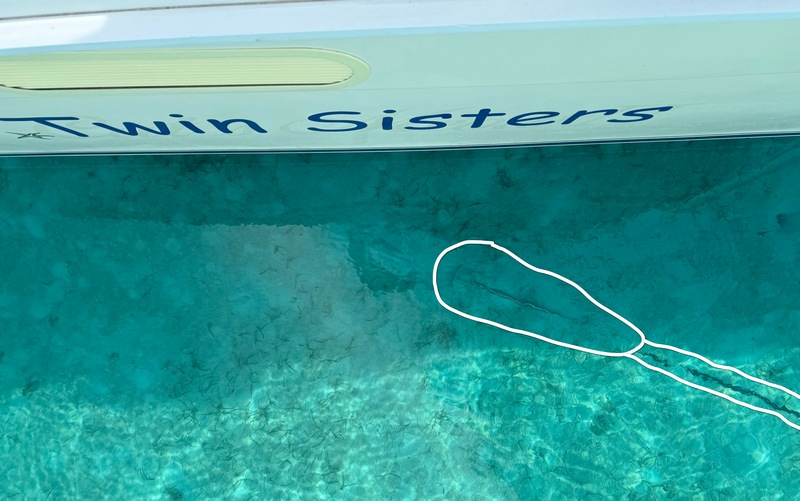

The combination of light winds & a full moon was a special treat. While the bottom under our boat seemed to be just flat sand, our underwater lights show much more detail at night. Some sort of creatures build underwater ant-hill looking things.

While the bottom under our boat seemed to be just flat sand, our underwater lights show much more detail at night. Some sort of creatures build underwater ant-hill looking things. In our 12 years in George Town, we’ve seen many changes. Never were there large yachts like this! This yacht, Voyager, is 300′ long & that strange extension is actually part of the ship (shown better in the insert). A week later, there were 3 more, smaller yachts lined up, “only” 120′ – 220′ long.

In our 12 years in George Town, we’ve seen many changes. Never were there large yachts like this! This yacht, Voyager, is 300′ long & that strange extension is actually part of the ship (shown better in the insert). A week later, there were 3 more, smaller yachts lined up, “only” 120′ – 220′ long. Lots of fun times at Corts “camp house” he built on Stocking Island, with some of the motley crew.

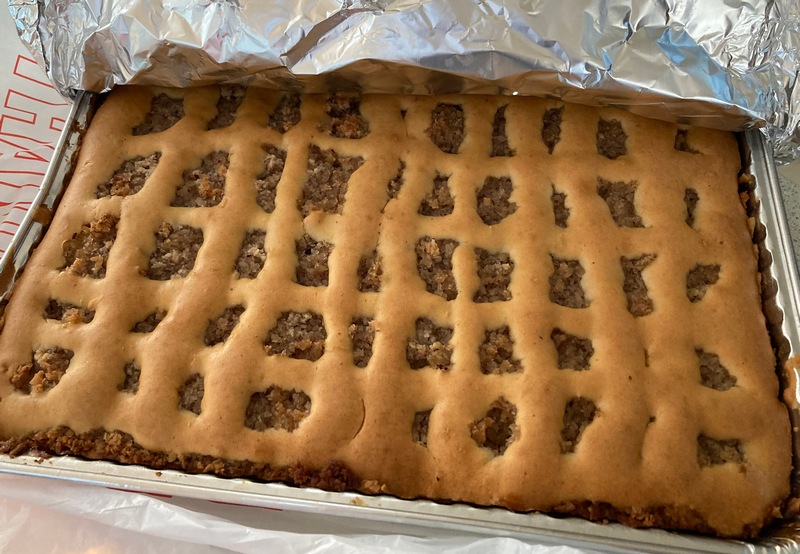

Lots of fun times at Corts “camp house” he built on Stocking Island, with some of the motley crew. Delicious coconut tart ordered from the in-town hair salon where we also buy our lobsters (of course!).

Delicious coconut tart ordered from the in-town hair salon where we also buy our lobsters (of course!). Finally! There is now a bakery (within walking distance) with various breads, pastries & yes, donuts!

Finally! There is now a bakery (within walking distance) with various breads, pastries & yes, donuts! We almost left the harbor on Friday the 13th, but it didn’t seem prudent & we were able to catch the annual “Rooftop Concert” the following day with fellow cruisers as the performers.

We almost left the harbor on Friday the 13th, but it didn’t seem prudent & we were able to catch the annual “Rooftop Concert” the following day with fellow cruisers as the performers. This year’s regatta t-shirt

This year’s regatta t-shirtAs we depart, the 44th Annual Cruising Regatta is about to get underway. It’s 2 weeks full of various activities from volleyball to a dinghy poker run to bocce ball to a talent show to sailboat racing. In addition to fun for the cruisers, over $16,000 is raised for the local schools & organizations.

While we sadly don’t plan on cruising down to George Town again (for various reasons), it’s been a great 12 visits over 16 years with lots of great memories!